Full Circle Biotechnology builds and deploys biological ecosystems to solve the biggest problems facing the food system.

Full Circle Biotechnology builds and deploys biological ecosystems to solve the biggest problems facing the food system.

Our facility beta makes protein powder from food, drink and agriculture byproducts in Bangkok.

That protein is being used by farmers in Thailand to reduce feed costs. Other impacts are improved animal health, better meat quality, higher yields and dramatically reduced carbon footprint.

We are a dedicated team of engineers, scientists and generalists, headquartered in Singapore, with operations in Thailand and presence across the world.

Our facility beta makes protein powder from food, drink and agriculture byproducts in Bangkok.

That protein is being used by farmers in Thailand to reduce feed costs. Other impacts are improved animal health, better meat quality, higher yields and dramatically reduced carbon footprint.

We are a dedicated team of engineers, scientists and generalists, headquartered in Singapore, with operations in Thailand and presence across the world.

Our facility beta makes protein powder from food, drink and agriculture byproducts in Bangkok.

That protein is being used by farmers in Thailand to reduce feed costs. Other impacts are improved animal health, better meat quality, higher yields and dramatically reduced carbon footprint.

We are a dedicated team of engineers, scientists and generalists, headquartered in Singapore, with operations in Thailand and presence across the world.

The world has the abundance to feed everyone.

Our mission is to unlock it.

The world has the abundance to feed everyone.

Our mission is to unlock it.

The hardest challenges in nutrition come from protein.

Advancements in (bio)tech haven't solved the most pressing of them.

Since 1990:

The price of semiconductors has fallen by 43%/

Deaths from communicable, maternal, perinatal, and nutritional conditions has fallen by 46%/

The price of meat, fish and poultry has risen by 5% in real terms/

Logistics, energy-efficiency and nutrition science have significantly improved.

the high cost of protein has not.

The hardest challenges in nutrition come from protein.

Advancements in (bio)tech haven't solved the most pressing of them.

Since 1990:

The price of semiconductors has fallen by 43%/

Deaths from communicable, maternal, perinatal, and nutritional conditions has fallen by 46%/

The price of meat, fish and poultry has risen by 5% in real terms/

Logistics, energy-efficiency and nutrition science have significantly improved.

the high cost of protein has not.

The hardest challenges in nutrition come from protein.

Advancements in (bio)tech haven't solved the most pressing of them.

Since 1990:

The price of semiconductors has fallen by 43%/

Deaths from communicable, maternal, perinatal, and nutritional conditions has fallen by 46%/

The price of meat, fish and poultry has risen by 5% in real terms/

Logistics, energy-efficiency and nutrition science have significantly improved.

the high cost of protein has not.

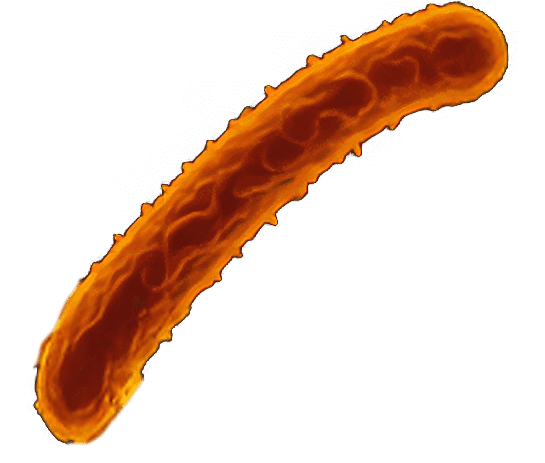

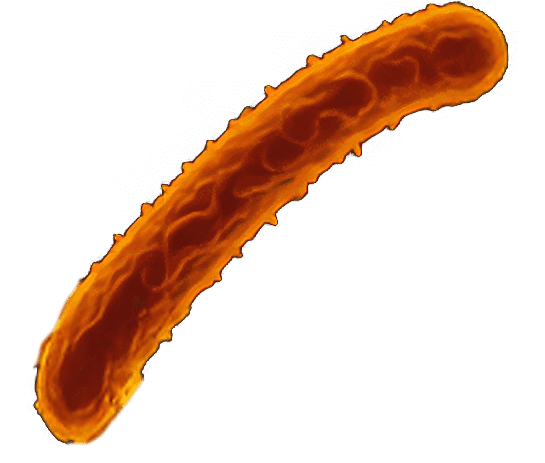

Using biotechnology to improve protein supply is one of the fastest, most scalable and least expensive ways to change the world.

Using biotechnology to improve protein supply is one of the fastest, most scalable and least expensive ways to change the world.

Using biotechnology to improve protein supply is one of the fastest, most scalable and least expensive ways to change the world.

Protein is the most expensive nutrient. Lower prices will change billions of people's lives.

Protein is the most carbon-intensive nutrient. Switching traditional animal feed protein with ultra-low carbon replacements could cut global emissions by about 1/8.

Protein supply-chains involve forced labour. forced labour is endemic in protein supply chains. Protein produced through biotechnology is fully traceable.

Swapping traditional protein sources for new, clean replacements will instantly create massive change. Swapping ingredients doesn't need new infrastructure and system changes

Protein is the most expensive nutrient. Lower prices will change billions of people's lives.

Protein is the most carbon-intensive nutrient. Switching traditional animal feed protein with ultra-low carbon replacements could cut global emissions by about 1/8.

Protein supply-chains involve forced labour. forced labour is endemic in protein supply chains. Protein produced through biotechnology is fully traceable.

Swapping traditional protein sources for new, clean replacements will instantly create massive change. Swapping ingredients doesn't need new infrastructure and system changes

Protein is the most expensive nutrient. Lower prices will change billions of people's lives.

Protein is the most carbon-intensive nutrient. Switching traditional animal feed protein with ultra-low carbon replacements could cut global emissions by about 1/8.

Protein supply-chains involve forced labour. forced labour is endemic in protein supply chains. Protein produced through biotechnology is fully traceable.

Swapping traditional protein sources for new, clean replacements will instantly create massive change. Swapping ingredients doesn't need new infrastructure and system changes

Our data prove real change is imminent.

Our data prove real change is imminent.

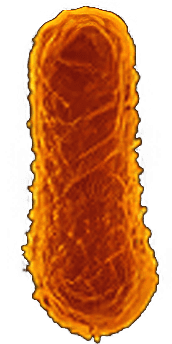

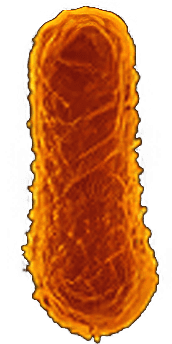

Our facility beta, deployed in Bangkok, converts byproducts into a variety of protein ingredients for specific use-cases.

Those ingredients have a protein content ranging from 30% to 70%.

These products are sold on the market. Since July 2024, they have saved 47 farmers in Thailand an average of 12% on their feed costs by producing quality feed at highly competitive prices. Feedback has been incredible and is invigorating the whole team.

Carbon sensors monitoring the production process have recorded carbon absorption about 40% of the time.

Our facility beta, deployed in Bangkok, converts byproducts into a variety of protein ingredients for specific use-cases.

Those ingredients have a protein content ranging from 30% to 70%.

These products are sold on the market. Since July 2024, they have saved 47 farmers in Thailand an average of 12% on their feed costs by producing quality feed at highly competitive prices. Feedback has been incredible and is invigorating the whole team.

Carbon sensors monitoring the production process have recorded carbon absorption about 40% of the time.

Our facility beta, deployed in Bangkok, converts byproducts into a variety of protein ingredients for specific use-cases.

Those ingredients have a protein content ranging from 30% to 70%.

These products are sold on the market. Since July 2024, they have saved 47 farmers in Thailand an average of 12% on their feed costs by producing quality feed at highly competitive prices. Feedback has been incredible and is invigorating the whole team.

Carbon sensors monitoring the production process have recorded carbon absorption about 40% of the time.

Team/

Opinions/

beta facility

149 Putthamonthon Sai 3 Road,

Nong Khang Phlu, Nong Khaem,

Bangkok 10160

(+66) 020 499 655

beta facility

149 Putthamonthon Sai 3 Road,

Nong Khang Phlu, Nong Khaem,

Bangkok 10160

(+66) 020 499 655

topco

160 Robinson Road, #14-04

Business Federation Centre

Singapore (068914)

Privacy

topco

160 Robinson Road, #14-04

Business Federation Centre

Singapore (068914)

Privacy